High Carbon Spring Tempering Steel Wire

Category:

Wire Rod

Keywords:

Wire Rod

PRODUCT DESCRIPTION

High Carbon Spring Tempering Steel Wire Description

High carbon steel is used to make spring tempered carbon steel wire. Commonly used grades of spring steel wire do not have a specific chemical name, such as 1065 or 1080, which is common in other types of high carbon steel products. Rather, they are specified and manufactured according to performance criteria specific to their primary end use, I .e., the manufacture of coil springs. These performance standards allow a range of carbon content, but there are other factors, such as tensile strength and bending/winding tests must be met within the specified range.

Mainly Divided Into Three Categories:

hard pull spring steel wire:Also known as HDMB spring wire, it is a cost-effective choice for many general-purpose applications. The carbon content ranges from 0.45 to 0.85 percent. Since it is usually not heat-treated after drawing, it has high strength and medium toughness. It is available in a variety of diameters and is manufactured in accordance with ASTM A227 (uncoated finish) and ASTM A764 (galvanized finish).

oil tempered spring steel wire:Also known as OTMB spring steel wire, it is an excellent general-purpose spring steel wire with improved performance compared to hard drawing. The carbon content ranges from 0.55 to 0.85 percent. After drawing, the oil-tempered wire rod is subjected to heat treatment and controlled cooling in an oil bath to increase its toughness while maintaining high tensile strength. This makes it particularly suitable for applications requiring high impact resistance or a large number of deflection cycles. Oil tempered spring steel wire is available in a variety of diameters and is manufactured in accordance with ASTM A229. This grade does not provide a galvanized finish.

music spring high quality steel wire:Also known as music wire or piano wire, it is a very high quality steel wire suitable for demanding applications. The carbon content ranges from 0.70 to 1.00 percent. The music wire is heat treated after drawing to relieve stress and toughen the wire while maintaining high tensile strength. The strings are typically 0.250 inches or less in diameter and are manufactured in accordance with ASTM A228. It has a variety of surface treatments to choose from, such as bright, phosphate, tin and zinc.

Scope of Application

Steel wire is widely used in the manufacture of many wire products.

Packing and delivery

Packing and shipping We can provide wooden pallet packaging,Wooden packing, Steel strapping packaging,Plastic packaging and other packaging methods.We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements.We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

Customer visit

Xintong Nonferrous Metals (Guangdong) Co., Ltd. operates in multiple countries and regions, including Asia, Europe, and North America, and has established long-term, stable cooperation with hundreds of clients worldwide. Through our strong international procurement and sales network, we are able to flexibly respond to changes in the global market and offer more competitive products and prices.

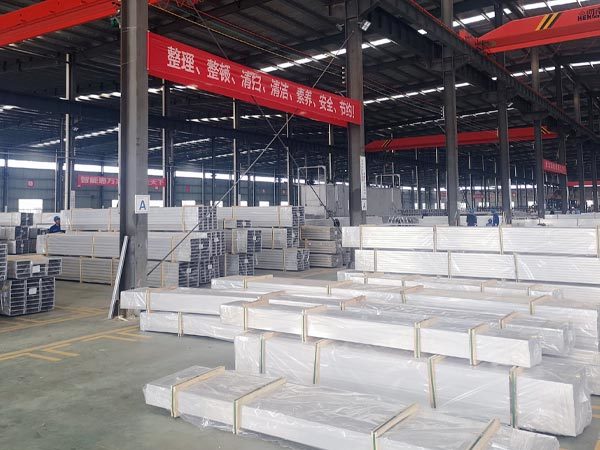

FACTORY

The company is equipped with a complete range of advanced equipment, mainly producing various products including carbon steel, stainless steel, galvanized steel, steel bars and wire rods.

Backed by strict full-process quality control, innovative production technologies and sufficient inventory, it can accurately meet the diversified and customized procurement needs of global customers.

APPLICATION

These products are widely used in key industries such as construction, energy, machinery, shipbuilding, petrochemicals and pressure vessels. With strict full-process quality control, innovative production technology and sufficient inventory, the company can accurately meet the diversified and customized procurement needs of global customers.

HONOR

WHY CHOOSE US?

High quality product and good price.

Good Pre-sale、on sale and after sales service.

Short delivery time.

Exported all over the world, with rich experience.

The products can be made completely according to the customer's requirements, and we have our own factory.

FAQ

Q1: What is your MOQ?

A: Usually our MOQ is one container, but it is different for some items, please contact us for details.

Q2:What is your terms of payment?

A:We usually accept T/T in advance, L/C for large sum.If you prefer other payments terms, please discuss.

Q3:What is your delivery time?

A:For products in stock, we can ship it within 7 days after receiving the deposit. For custom order, production time is 15-30 workdays after received the deposit.

Q4:How could you guarantee your products?

A:Mill Test Certification is supplied with shipment, We also accept and support the third-party inspection.We also could issue the warranty to customer to guarantee the quality.

Q5: Will all costs be clear?

A:Our quotation is easy to understand and will not incur any additional costs.

Q6:Can you give warranty of your products?

A:Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

RELATED PRODUCTS