Aluminum alloy profile

Category:

Aluminum alloy profile

Keywords:

Aluminum alloy profile

PRODUCT DESCRIPTION

Aluminum alloy profiles are the backbone of countless modern structures and products. Known for their lightweight strength, corrosion resistance, and sleek appearance, they are widely used in architecture, transportation, electronics, and industrial manufacturing. Through advanced extrusion technology, aluminum alloy can be shaped into precise forms—frames, rails, enclosures, or complex structural components—meeting both functional and aesthetic demands.

Their exceptional durability ensures long-lasting performance even in harsh environments, while their recyclability supports sustainable development. Whether it’s the frame of a high-rise curtain wall, the structure of a solar panel, or the chassis of an electric vehicle, aluminum alloy profiles bring strength, efficiency, and elegance to every design.

Aluminum alloy profiles are metal materials with specific cross-sectional shapes made mainly of aluminum through processes such as melting, extrusion, and surface treatment. Its characteristics of light weight, corrosion resistance, high strength, and easy processing make it widely used in fields such as construction, transportation, electronic appliances, and industrial equipment.

| Parameter | Specifications |

| Alloy Series | 6063 (general construction), 6061 (high-strength), 6082 (marine/bridges), 7005 (aerospace) |

| Main specifications | The 60 series, 70 series, 90 series, 105 series, 110 series, 118 series, 120 series, 125 series, etc., among which the 60 series, 70 series, and 90 series are more commonly used. |

| Cross-Section Size | 10×10mm to 300×300mm (common sizes: 80×80mm for construction) |

| Wall Thickness | 0.8, 0.9, 1.0, 1.2, 1.4, 1.5, 2.0, 3.0, etc. |

| Surface Treatment | - Anodizing (10-25μm film thickness) |

| - Electrophoretic Coating (weather-resistant) | |

| - Powder Coating (color variety) | |

| Mechanical Properties | - Tensile Strength: 150-350 MPa |

| - Yield Strength: 100-300 MPa | |

| - Elongation: 8%-15% | |

| Dimensional Tolerance | GB/T 14846 (China) or EN 12020 (EU), typically ±0.1mm to ±1mm |

| Standard Length | 6 meters (customizable: 3-12 meters) |

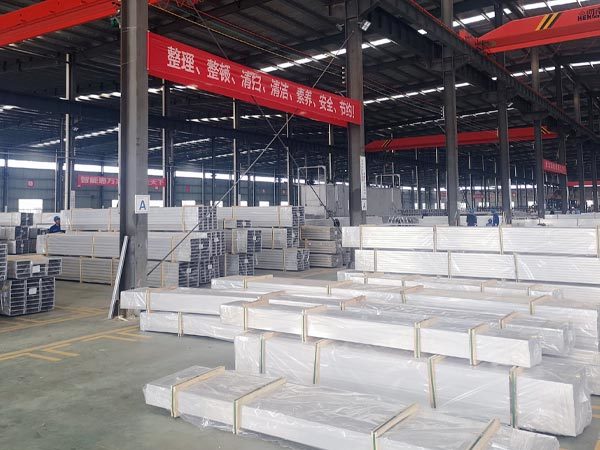

Packing and delivery

We strictly implement the product factory inspection system. For the delivered steel products, the company provides quality certificates to ensure their quality. In order for the products to arrive safely, we choose sturdy sea-resistant packaging or according to your needs.Professional and sturdy packaging to protect steel to the greatest extent and avoid bumps and scratches during transportation.

Customer visit

Xintong Nonferrous Metals (Guangdong) Co., Ltd. operates in multiple countries and regions, including Asia, Europe, and North America, and has established long-term, stable cooperation with hundreds of clients worldwide. Through our strong international procurement and sales network, we are able to flexibly respond to changes in the global market and offer more competitive products and prices.

FACTORY

The company is equipped with a complete range of advanced equipment, mainly producing various products including carbon steel, stainless steel, galvanized steel, steel bars and wire rods.

Backed by strict full-process quality control, innovative production technologies and sufficient inventory, it can accurately meet the diversified and customized procurement needs of global customers.

APPLICATION

These products are widely used in key industries such as construction, energy, machinery, shipbuilding, petrochemicals and pressure vessels. With strict full-process quality control, innovative production technology and sufficient inventory, the company can accurately meet the diversified and customized procurement needs of global customers.

HONOR

WHY CHOOSE US?

High quality product and good price.

Good Pre-sale、on sale and after sales service.

Short delivery time.

Exported all over the world, with rich experience.

The products can be made completely according to the customer's requirements, and we have our own factory.

FAQ

Q1: What is your MOQ?

A: Usually our MOQ is one container, but it is different for some items, please contact us for details.

Q2:What is your terms of payment?

A:We usually accept T/T in advance, L/C for large sum.If you prefer other payments terms, please discuss.

Q3:What is your delivery time?

A:For products in stock, we can ship it within 7 days after receiving the deposit. For custom order, production time is 15-30 workdays after received the deposit.

Q4:How could you guarantee your products?

A:Mill Test Certification is supplied with shipment, We also accept and support the third-party inspection.We also could issue the warranty to customer to guarantee the quality.

Q5: Will all costs be clear?

A:Our quotation is easy to understand and will not incur any additional costs.

Q6:Can you give warranty of your products?

A:Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

RELATED PRODUCTS